Metal Fabrication Equipment From Sanson

Sanson Machinery Group sells and services complete machinery solutions for all of your metal fabrication and machining applications. We offer our comprehensive metal fabrication equipment sales and services throughout the United States including Washington, Oregon, Idaho, Northern California, Northern Nevada, Alaska, Hawaii and British Columbia, Canada. Our wide variety of new and used machinery includes cutting edge technology and various metal processing techniques to help you achieve the desired result for every project. We take pride in offering the best machinery in the market for ultimate precision and accuracy. Additionally, we back up every piece of machinery, manufacturing equipment and tooling with guaranteed satisfaction and continued service.

In addition to complete metal fabrication equipment sales, we also offer complete service and repair for all existing metal fabrication equipment in your facility. Our service technicians are some of the best in the industry. We strive for the success and productivity of our customers through equipment sales and service throughout the Northwest United States.

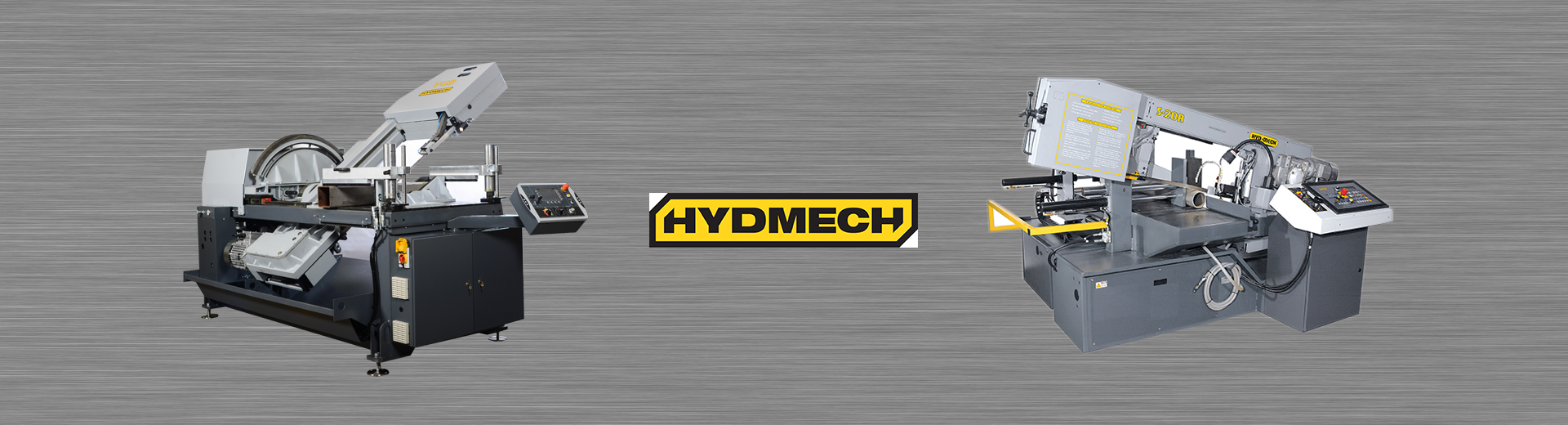

We carry a wide variety of metal cutting systems, forming technology, welding equipment, saws, shears, and tooling to complete your manufacturing facility. We will guide you through the machine tool purchase process to ensure you are purchasing the piece of equipment that will meet your needs.

We are members of AMT, MDNA & AMEA

AMT – The Association For Manufacturing Technology represents and promotes U.S.-based manufacturing technology and its members—those who design, build, sell, and service the continuously evolving technology that lies at the heart of manufacturing.

MDNA – Machinery Dealers National Association is an international, nonprofit trade association dedicated to the promotion of the used machinery industry. It was established in 1941 to assure buyers of the integrity and reliability of the hundreds of used machinery dealers from around the world that are members of our Association.

AMEA – The Association of Machinery and Equipment Appraisers (AMEA) is a nonprofit professional association whose mission is to accredit our certified equipment appraisers. Through the promotion of standards of professional practice, ethical conduct, and market-based experience, our company has continued to thrive on its original ethics since our establishment by the Machinery Dealers National Association (MDNA) in 1983. Learn more about AMEA appraiser qualifications here.

Manufacturer Spotlight: AKS Cutting Systems

AKS Cutting Systems manufactures CNC cutting machines including plasma cutters, waterjet cutting systems and oxy-fuel burning tables for the sheet metal, plate metal, and fabricating industries.

AKS has introduced two revolutionary cutting table features exclusive to our products:

- robo-kut robotic plasma and waterjet beveling system

- tube-kut pipe and tube cutting systems

AKS Cutting Systems and our products have a reputation for durability, accuracy and reliability, with thousands of machine installations worldwide.

AKS dura-kut 2021 from AKS Cutting Systems on Vimeo.