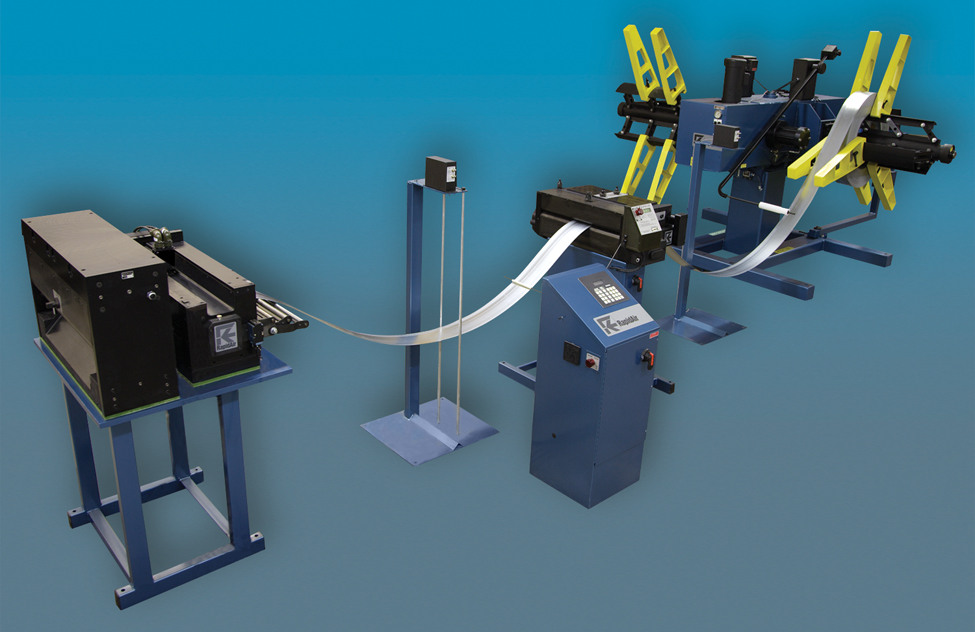

A Rapid-Air cut-to-length machine with servo feed, or servo feed straightener (KBX100), is a real production booster for both long or short length stamping operations.These integrated units may provide a maximum feed stroke of up to 999 inches or more, and handle maximum stock widths up to 24 inches. Consult our application engineers regarding special control programs available to meet your specific needs.A user-friendly, programmable console key pad that controls all functions gives you the flexibility to conveniently handle quick job changes, short runs or just-in-time manufacturing requirements.

Controls feature batch and total count display.KBX Series servo feed/straightener models combine a high performance feed with a precision stock

straightener saving lots of shop floor space, because integrated design eliminates a material loop between the feed and straightener. Combined with a Rapid-Air stock cutter, you have a modular, compact automated cut-to-length system that can’t be beat.

If you are looking for a productivity advantage and are processing materials in thicknesses from .008″ to .250″, coil strip widths up to 84″, coil weights up to 75,000 pounds, and coil processing speeds up to 80 SPM and 300 FPM, a Cut to Length or Blanking line from COE Press Equipment can help you keep work in-house and gain that competitive edge. Whether your applications requires hydraulic, mechanical or oscillating shears, our experience in providing world-class Blanking and Cut to Length Lines allows us to design and build a system to meet your exacting requirements. Our wide range of stacking systems includes single station or multiple station, finger drop stackers, air drop stackers, and our recently developed magnetic combination stacker.

Our cut to length specialists at Sanson Machinery are available to discuss the specific needs of your metal processing applications to determine the best cut to length solutions for your facility.