Sanson Machinery offers complete solutions for all of your press room equipment needs. Our selection of press room equipment includes comprehensive press equipment options to accommodate all of your metal processing needs. The press room equipment offered by Sanson Machinery includes cutting edge technology and the most innovative press equipment in the industry. Our full inventory is available to all our customers in order to achieve the desired results of your press room application. No matter which pieces of equipment you choose, you will find that each produces high quality products with extreme precision and accuracy.

Some of our press room equipment selections include:

- Press Brakes & Press Brake Tooling

- Cut to length machines

- Backgauge systems

- Punch presses

- Rolls

- Punches

- Shears

- Customized press room equipment

A History of Innovation

The year was 1959 when Dick Nordlof, an enterprising partner of Mechanical Tool and Engineering Company, located in Rockford, Illinois, pioneered and innovated the first self-contained air feed designed to drastically improve the metal stamping process. It was a device destined to forever change press room operations.

Mechanical Tool and Engineering was in the business of making tools and dies and producing precision stampings from some of the first, very complex and progressive dies in the country. It soon became evident to Nordlof, an MIT graduate engineer, that the dies couldn’t be used to their fullest capability, because there were no precision feeding devices on the market. And thus, with the introduction of a new air feed device, and Dick’s brother Ron Nordlof in charge of manufacturing, Rapid-Air was born.

Air Feeds

Improve production with faster material flow speeds

and uniform accurate progressions.

Rapid-Air pioneered the first compact air feed with internal air circuitry, setting the technological and performance standards for the industry. The unique dual air valve system provides outstanding performance backed by reliability that has made Rapid-Air the recognized innovator and leader in air feed technology.

Superior versatility.

Rapid-Air feeds offer unmatched production flexibility. Their cost-effective operation often justifies permanent installation on die sets to minimize job setup time.

Easy installation and removal make Rapid-Air units the most versatile type of feeding equipment available. Two bolts are all it takes to install one. Stroke length and speed adjustments are positioned for easy access.

Feed a variety of material in any direction.

All kinds of coil stock plus paper, plastic, wire, fabrics, foil, tubing, extruded and preformed shapes can be fed at short and long progressions, and at different production speeds. Rapid-Air feeds are unequalled in handling both thin and delicate materials. Several actuation options allow our feeds to be used on standard production presses, electric presses, hydraulic presses, wire forming machines, multi-slide machines and special machines.

We offer a comprehensive range of standard models to feed flat stock up to 16” (406mm) wide, .150” (3.81mm) thick, and in lengths up to 20” (508mm). Pulling capacities of up to 250 pounds (114kg) are available on heavy duty models. Our smallest feed is capable of 260 cycles per minute at a 2” (50.8mm) progression and can cycle much faster at shorter progressions. Special models are available to meet unusual feeding requirements

Stock Reels

MODEL R24A

Powered Reel

100 SERIES STOCK REELS

The most complete selection available from any source. Powered and non-powered. Adjustable and fixed centers.

Max. capacities 50-500 lbs. (22-227kg).

We build our stock reels for lasting durability featuring heavy duty shafts with full bearing support to handle heavy coil loads day in and day out, rugged coil centering arms, and sturdy all steel cabinets and support bases. The options and accessories for each of our models enables you to configure a reel practically any way you want for dependable payoff of coil stock.

Powered reels.

Electric drive-powered reels are made for ease of operation with innovative standard features such as our proportional control system. This top-of-the-line patented system features variable speed capability, electronic loop height adjustment and loop sensing arm range control.

Request A Quote Here

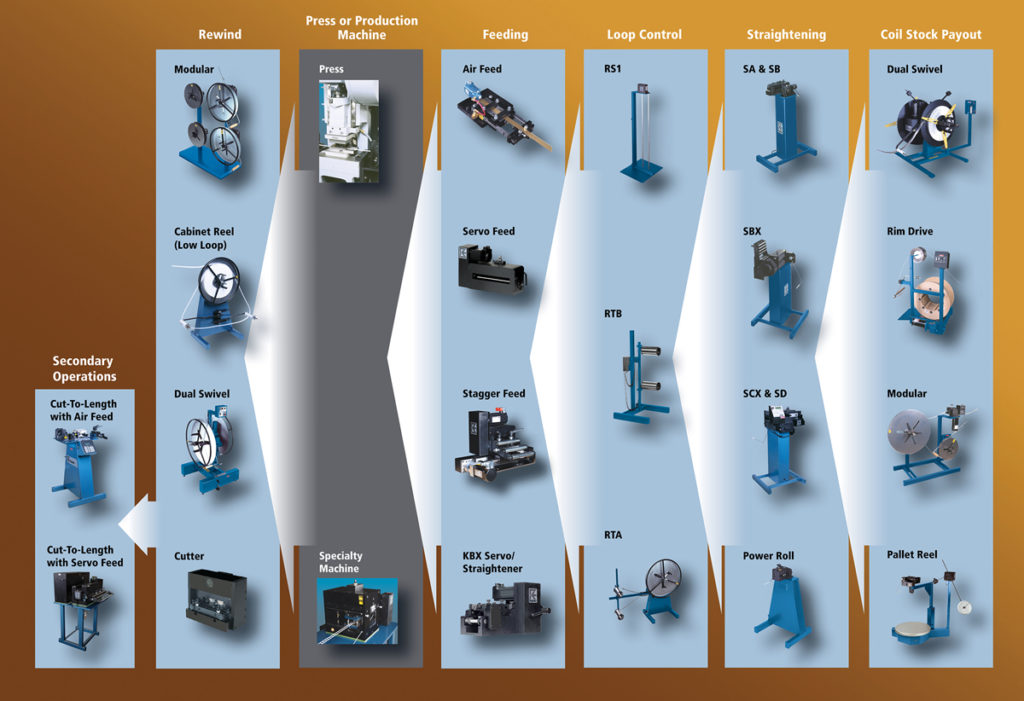

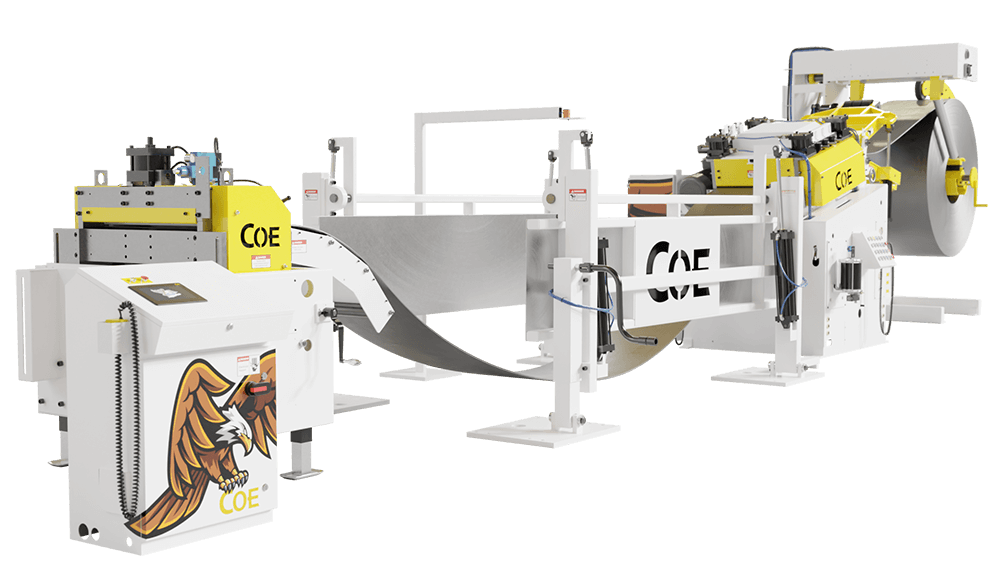

COE Press Equipment designs and manufactures a complete line of premiere coil handling and servo roll feed equipment from stand-alone roll feeds, straighteners, decoilers, and shears to completely integrated feed line systems and cut-to-length lines. COE provides one-stop shop capability starting with its top-notch engineering staff focused on R&D right through to fabrication, CNC machining, assembly, paint and electrical. This vertically integrated approach ensures development and delivery of high-quality coil feeding equipment and systems in a timely manner that is best-suited to each company’s particular need.

We supply and service a wide variety of global markets and industries including automotive, appliance, lighting, metal processing, housewares, lawn and garden, contract stampers, tool and die builders, and many others.

Conventional Coil Feed Lines

Request A Quote Here

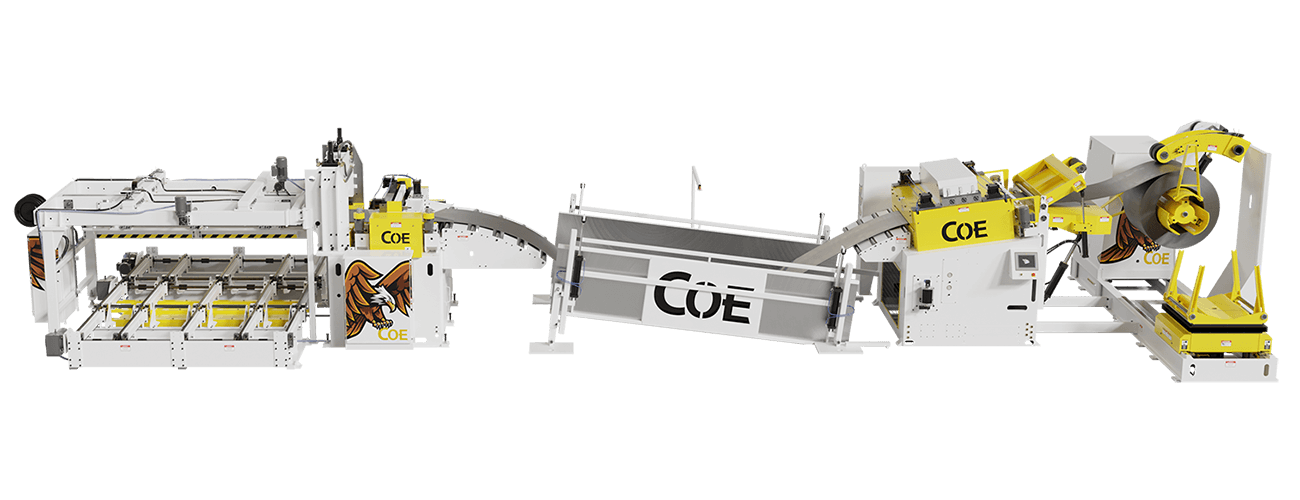

Cut-to-Length CTL Coil Lines

A cut-to-length CTL coil line processes metal coil rolls by uncoiling, straightening, shearing to length and stacking of sheet metal blanks. These lines provide automation that ensures accurate feeding, shearing, and flattening for a variety of industries. Bringing these lines into your fabricating operations can eliminate blank processing fees and help you gain a competitive edge by taking control of your inventory and production schedules with your own blanking coil line. In-house CTL capability gives you flexibility to run blanks in the sizes you need when you need them.

COE cut-to-length CTL coil lines are configured from our standard and performance-proven feeds, straighteners and reels coupled with COE shear and stacking solutions to deliver a complete integrated blanking coil line that is right-sized to your particular needs. Whether you’re a general fabricator, OEM or stamper, COE’s cut-to-length CTL lines can be built to your specific needs. You get proven designs manufactured with attention to detail and backed by the COE Assurance 24/7/365 service advantage.

Request A Quote Here

If you require any specialized press room equipment that you do not see listed, we are happy to find any custom piece of equipment. Our press room equipment specialists will help you analyze your press room applications and determine which press room equipment choices are optimal for your production needs.

Many of our press room equipment options include energy efficiency and energy saving features that will improve the cost-effectiveness of each project. Additionally, we strive to include as many safety features as possible with each piece of equipment sold by Sanson Machinery to ensure the safety of your machine operators and reduce any downtime incurred by accidents in the workplace.

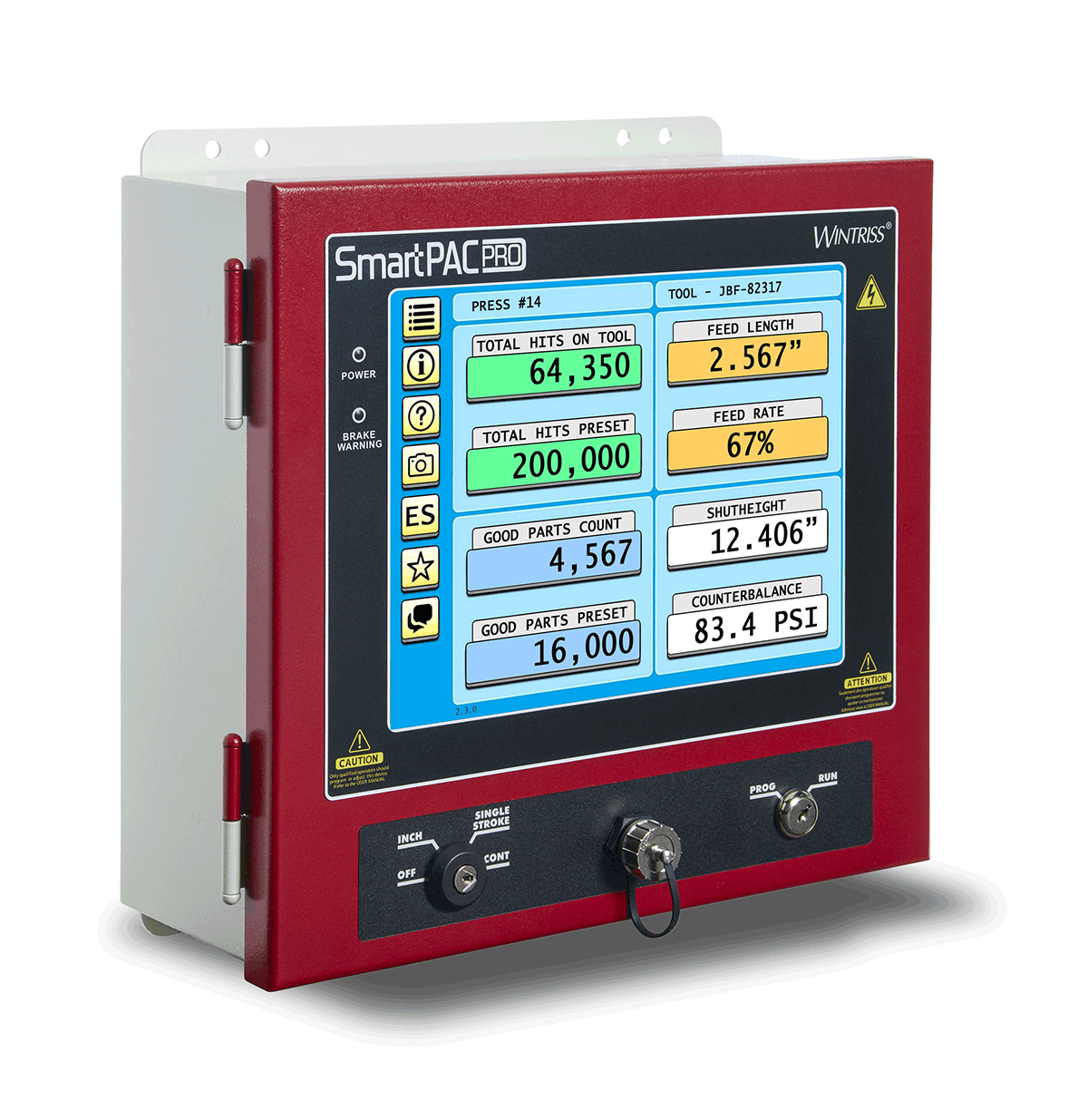

The Wintriss SmartPAC PRO sets the standard for complete Press Automation Control. With a large 12 inch color touch screen, advanced communications, superior graphics, on-screen help at the touch of a button, and many performance enhancements, it’s the most exciting control product since… well… the original SmartPAC!

SmartPAC PRO

Wintriss Controls has raised the bar once again with the introduction of the SmartPAC PRO Press Automation Controller. The SmartPAC PRO features a large color touch screen, advanced communications, superior graphics and unparalleled connectivity. In addition to its core features, the SmartPAC PRO incorporates numerous performance enhancements. Here are some of the powerful capabilities that make the SmartPAC PRO the most exciting control product since… well… the SmartPAC 2:

WPC 2000 Wintriss Press Control

The WPC 2000 clutch/brake controls is your best choice for press safety, reliability and support.

The WPC 2000 Clutch/Brake Control is a feature packed, easy-to-use, dual microprocessor based clutch/brake control system for part revolution mechanical power presses. With its two independent microprocessor systems, the WPC 2000 provides diverse redundancy, for optimum clutch/brake control reliability and greater operator safety.

Since establishment in 1962 and throughout more than 5 decades of development, SEYI has always been persistent on professional operation and advanced technology in research and development, so we can protect customer’s interests by providing safe product of excellent quality, reasonable price, fast delivery and thorough service.

We can help you find the right solutions for your press room equipment needs with our comprehensive selection of press room equipment and additional metal fabrication machinery options. Our press room equipment specialists have helped many customers complete their press room needs, whether it be a single piece of press room machinery or outfitting the facility with an entirely new press room. We offer options for updating your current press equipment as well as replacing entire pieces of machinery. No matter how you are looking to improve your press room, we have the right solutions to help you make it happen! Contact Sanson Machinery today!