Sanson Machinery offers a full line of punch press machinery ranging from simple, manual punch presses to large, hydraulic CNC punch presses. Each punch press is designed for optimal use in specific types of applications and capacities. Our punch press specialists can help you determine the advantages of each punch press we offer and which specific type of punch press is optimal for your metal working applications.

Punch presses are used to cut circular holes in various types of sheet metal for a wide variety of applications. Mechanical punch presses are typically the smallest and most simple kind of punch presses, offering only one die set. This means that the production options are rather limited in comparison to a more complex punch press machine. This particular type of punch press is ideal for smaller productions or short runs. If your metal fabrication application is relatively simple, this is may be the ideal punch press for your application.

On the other end of the spectrum, hydraulic CNC punch presses are rather complex and ideal for large, complex metal fabrication applications. These punch presses typically use several die sets and have many production options for you to choose from. This type of punch press is more ideal for high customized jobs than any other type of punch press. These punch presses are also better designed for very heavy and large pieces of sheet metal.

There are many options for customization on any punch press, including additional safety features and die sets that you can choose from. Sanson Machinery offers the very best punch presses from all our manufacturers for optimal performance regardless of your application. With various weight capacities, control options, software, power consumption, size of working area, and speed of production as just some of the options you can choose for your punch press, your options are almost unlimited. We can create a customized punch press to fulfill your specific requirements and achieve your desired outcome every time. Our punch press specialists will help you analyze your punch press application and determine the right to meet all of your production requirements.

Punching Machines

The constant research and technological innovation has allowed Euromac to create a range CNC punching machines that are performing, highly productive and with the lowest running costs. We offer numerous and versatile configurations that will satisfy all of your production needs, from the small to large industry optimizing whatever your requirements are.

STX flex

The STX meets the requirement for a high performance and productive machine reducing at the same time the operating costs.

XT

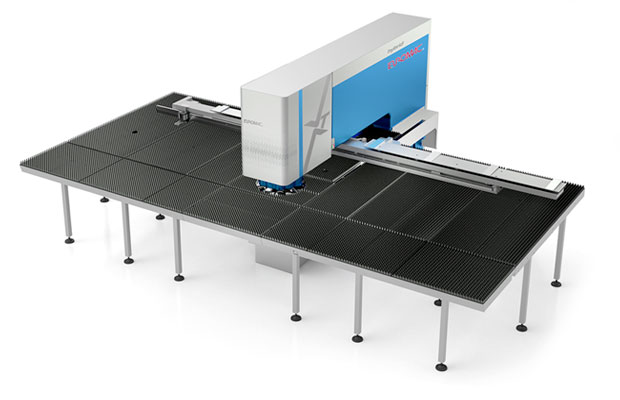

Discover the new punching machines generation.

Euromac’s XT new high performance punching machine, is flexible according to any production requirement.

Fully configurable, hydraulic, hybrid, electric, 6 or 12 turret machine.

Working area of 3000 x 1500 mm without repositioning.

Punching speed:

– up to 1080 strokes per minute for nibbling 1 mm pitch

– up to 460 strokes per minute for punching 20 mm pitch

Mtx plus flex

The new frame with an increase of dimensions enables the machine to operate with higher speeds thus ensuring greater stability and working precision.