Sanson Machinery offers a wide variety of shears and metal cutting equipment to meet the needs of your metal fabrication application. Metal cutting shears are typically used to cut large pieces of sheet metal. Shears cut large pieces of sheet metal to the proper dimensions before continuing in the metal processing application of your choice. This metal cutting option is commonly used in large manufacturing in order to cut each piece of sheet metal quickly with high precision and minimal distortion of the piece of sheet metal.

Shears are available in a variety of cutting capacities, speeds, and power mechanisms for your convenience. Choosing the right capacity, speed, and power mechanism is essential to creating the desired outcome for your metal fabrication project. While mechanical shears are generally less expensive, their capabilities are also limited in comparison to more complex shears such as a hydraulic shear. Larger shears are also more capable of producing a wide variety of projects, speeds, dimensions, and capacities than smaller shears. Although some larger shears may compromise in the overall quality of the piece being produced, the shear technology available today is typically high quality enough that most large shears are capable of producing a product as high quality as smaller shears.

The feed and speed of the shear is also important factors. You need to make sure that the shear your purchase can meet your production speed requirements without sacrificing the quality of your finished product. Additionally the type of feed is essential to your application depending on the type of material you are cutting and what your desired outcome is for each piece of sheet metal. The shear specialists with Sanson Machinery can help you determine the requirements of your shear while you are in the purchase process. We thoroughly analyze your metal processing application before helping you select the right options for your shear. If you are planning a wide variety of applications for your shear in the future, you may want to consider a more complex shear in order to meet those requirements.

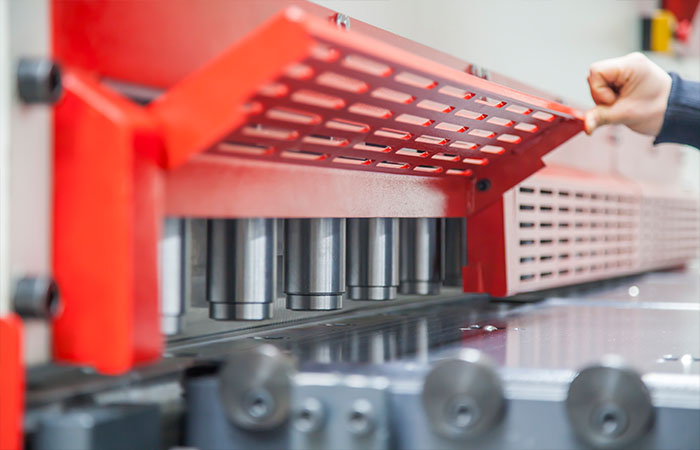

Dener CNC shears provide robust mechanics, precise hydraulic ball screw gauge and easy to use CNC controller on high productivity cutting machines. Dener shears have a metal cutting thickness capacity from 6 mm to 20 mm, cutting length capacity from 3 m to 6 m as standard and according to a special demand, customized machines are available.

Dener shears are made of solid welded steel, built for long operation time. The design of the frame, the cutting beam and the rear gauge ensure maximum rigidity and resistance to torsion and deformation. Due to its powerful design, customers can obtain the highest quality of cut.

With an easy-to-use CNC controller, the operator enters the thickness and type of material and the controller automatically adjusts the cutting angle and blade clearance.

REQUEST A QUOTE

AS SERIES CNC GUILLOTINE SHEAR

AS Series CNC Guillotine Shear

Dener CNC Guillotine Shears provide, rock solid mechanics, hydraulic, accurate ball screw back gauge, user friendly CNC Controller high productive shearing machines. Dener Shears are starring form 6 mm up to 20 mm thickness cutting length from 3 mt up to 6 mt as a standard and according to the special demanded higher capacity machines are available.

Dener Guillotine Shears have strong welded steel construction suitable for long operation time. The design of the frame, cutting beam and back gauge to ensure highest rigidity and resistance to torsions and deformations. With the strong design customers can get maximum cutting quality.

With Easy to use CNC controller operator enters the thickness and the type of the material and controller automatically adjust the cutting angel and blade gap.

Standard Equipment

• ESA S 530 CNC Control Unit

• Automatic hydraulic blade gap adjustment.

• Hydraulic Hold Down Pads

• Ball integrated front tables

• T-slot front feedings arm

• Motorized backgauge system

• Foot pedal with emergency stop button

• Front Protection Frame

• Curtain Light Guards

• Shadow line.

Optional Equipment

• Safety system for CE norms.

• Manual Centralized Lubrication System

• Oil Cooling System

• Pneumatic thin sheet support system

• Laser cutting line

FULL DENER SHEAR CATALOGUE AND MODELS