As part of our complete metal fabrication machinery offerings, Sanson Machinery offers a wide variety of spot welding and chiller equipment.

SpotWelders

Sanson Machinery offers a wide variety of spotwelders to complete the detail welding necessary for any metal fabrication process. The welding equipment available from Sanson Machinery consists of a wide variety of tips and tongs to help you achieve the desired weld for any given project including standard tongs, standard tips, flat tips, and offset tips. We also offer welders in varying capacities, inputs, and outputs to help you achieve the desired outcome of your spot welding. Our spot welders are also available in styles that can be either water cooled or air cooled depending on the type of welder you select.

Rocker Arm Seam Welder

MODELS RS1 and RS2

Air operated rocker arm seam welders in KVA sizes 10-15-20-30 furnished for operation on one of the following voltages 230 or 460 power supply. (Other voltages available)

| STANDARD FEATURES | |

|

|

REQUEST QUOTE

Air Operated Rocker Arm Spot Welder

MODELS AR1,2,3,& 4

Heavy Duty Air Operated Rocker Arm Spot Welders in KVA Sizes 10-15-20-30-50-75-100-150-200 Furnished For Operation On One of the Following Voltages 208, 230 or ,460, 575. (Other Voltages Available). These machines offer high efficiency welding for sheet metal and can be adjusted to access a variety of work piece shapes.

| STANDARD FEATURES | |

|

|

REQUEST QUOTE

Foot Operated Rocker Arm Spot Welder

MODEL FR1 AND FR2

Heavy Duty Foot Operated Rocker Arm Spot Welders in KVA Sizes 10-15-20-30 Furnished For Operation On One of the Following Voltages 208, 230 or 460, 575 (Other Voltages Available).

| STANDARD FEATURES | |

|

Universal Horns — Provides 90° and 30° Mounting of Holders Swivel Lower Horn Holder-Column Mounted and Adjustable Vertically. Quick Acting Clamping Devices For Adjusting And Securing Horns and Lower Swivel-Eliminates Spreading and Deforming of Casting When Making Necessary Adjustments. Water Cooled Ejector Type Electrode Holders. Water Cooled Transformer With Vacuum Impregnated Coils and Positive Locking Tap Switch. Limit Switch Initiation Complete With U.L. Approved Primary Contractor Cast Aluminum Hood For Easy Access and Concealment of Rocker Arm Bearings Swivel Mounted Foot Treadle 1 Inch Diameter Tip Holders |

|

REQUEST QUOTE

Chillers

Industrial chillers are used to cool and regulate the temperature of certain pieces of metal fabrication equipment. During the metal fabrication process, many pieces of machinery or other equipment can become overheated with can cause malfunction of the equipment or warping to the pieces of metal being produced. The use of industrial chillers helps to combat this problem, particularly with pieces of equipment that emit extreme heat such as welders. Most chillers use a method of extracting heat either through air or water, allowing the machine and the piece of metal to sufficiently cool and prevent any potential damage as the result overheating.

The spot welder and chiller specialists at Sanson Machinery will discuss your current metal fabrication applications and discover your specific spot welder and chiller needs. We will make customized recommendations for equipment that will meet the requirements of your current and upcoming metal processing projects and applications. We are happy to answer any questions you have regarding the use of our spot welders or chillers in your applications.

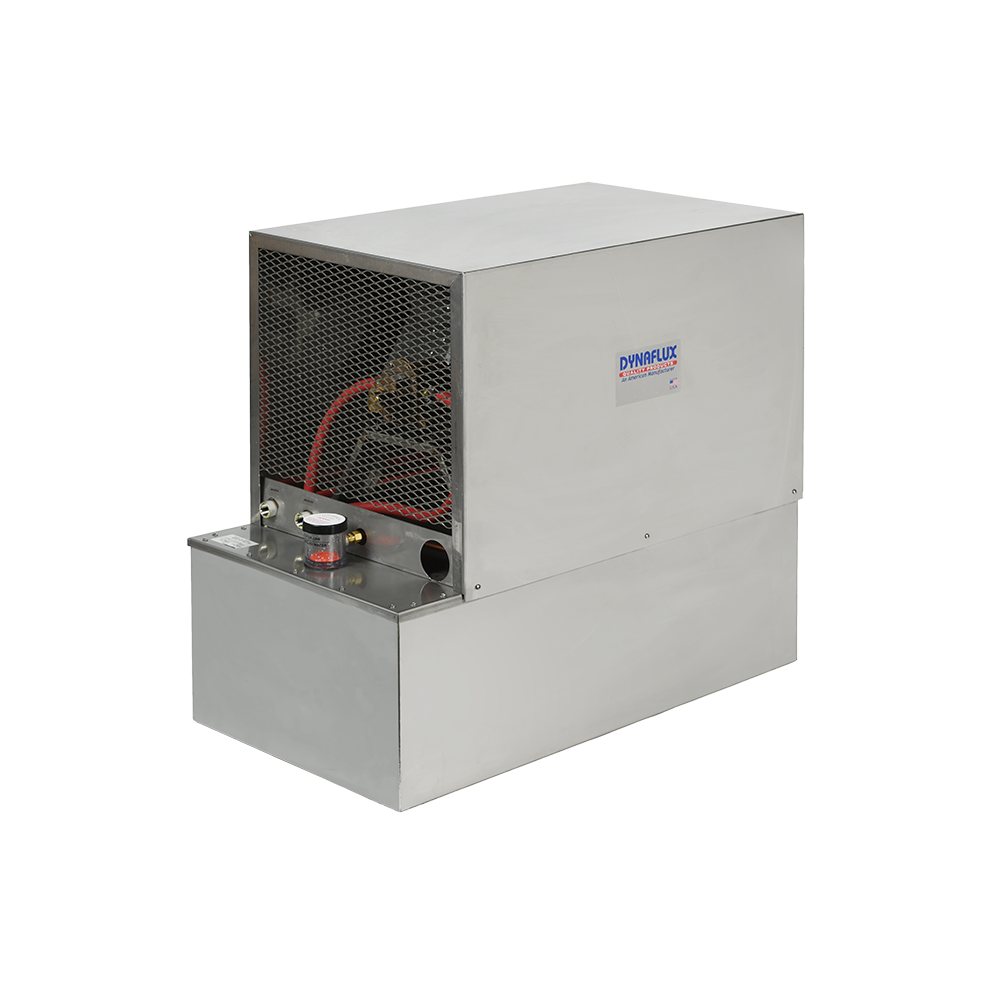

Dynaflux is a global supplier of welding equipment. A leader in chemical manufacturing since 1972, Dynaflux offers a complete line of anti-spatter products, visible liquid dye penetrant testing, cutting fluids, and galvanizing sprays. Dedicated to the welding industry, we supply replacement lenses and face shields, water cooling systems, and heat tint removal solutions. Through comprehensive manufacturing and industry leading product performance we are dedicated to providing solutions to meet the demands of the metal workings industry.

R1100 V/G Cooling System

Specifications

- Factory set at 50 psi adjustable to 80 psi

- 3 gallon reservoir

- 115 or 230 VAC / 1 ph-50 / 60 Hz

- 5.6 / 2.8 amp: 60 Hz

- 15,000 BTU

- Dimensions:23″ L x 11″ W x 14.75″ H

- 1/4″ FPT(water in /out) with 5/8″LH Standard Inert Gas Fitting

- Net weight: 42 lbs/19 kg

- Foam packed for UPS shipment

R1100 G: Rotary GEAR Pump

- 1.8 gpm at 50 psi

- Built in by-pass to tank.

R1100 V: Rotary VANE Pump

1.7 gpm at 50 psi

REQUEST QUOTE

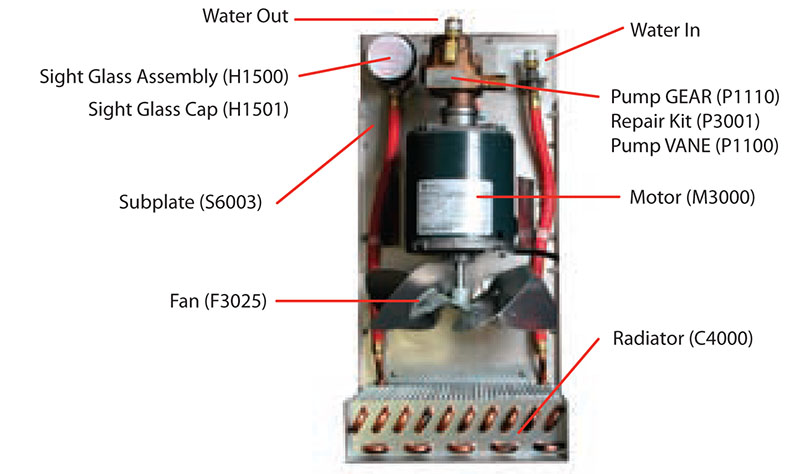

R4000 Cooling System

Specifications

- Factory set at 50 psi adjustable to 100 psi

- 25 gallon reservoir

- 115 / 230 VAC 50 / 60 Hz 1 ph

- 14.6 / 7.3 amp : 60 Hz 1 ph

- 230 / 190 VAC 50 / 60 Hz 3 ph

- 460 / 380 VAC 50 / 60 Hz 3 ph

- 5.4 / 2.7 amp: 60 Hz 3 ph

- 55,000 BTU

- Dimensions: 36″L x 19.5″W x 35″H

- 1/2″ FPT SS Pipe – water in and out

- Visible water level / water flow sight glass

- Net weight: 170 lbs / 77 kg

R4000: Rotary GEAR Pump (only)

- 10.0 gpm at 50 psi

- Built in by-pass to tank

- Rebuildable Pump (Repair Kit No. P4018)

System Features

- Stainless steel construction eliminates coolant contamination due to electrolysis or chemical reactions.

- All units are plumbed with copper tubing and reinforced hose.

- New extended life pump.

- Air flows into patented high efficiency radiator first for maximum efficiency.

- No external plumbing is required because of closed loop water system.

- A water level float gauge and filler cap are combined in a single unit multi-purpose sight glass which enables operator to observe return water at a distance.

REQUEST QUOTE

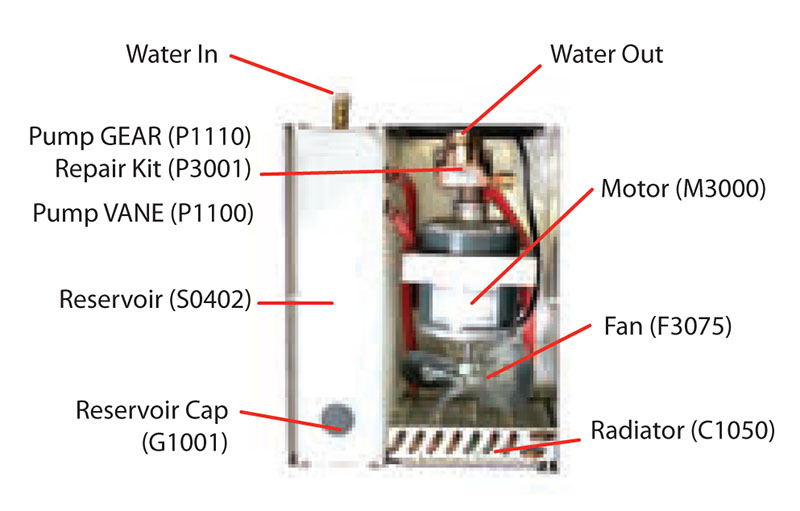

Procool PC2 V/G Cooling System

Specifications

- Factory set at 50 psi adjustable to 80 psi

- 3 gallon reservoir

- 115 or 230 VAC / 1 ph-50/60Hz

- 5.6 / 2.8 amp:60 Hz

- 12,000 BTU

- Dimensions: 18″L x 14″W x 9″H

- Net weight: 37 lbs / 17 kg

- Foam packed for UPS shipment

PCIIG: Rotary GEAR Pump

- 1.8 gpm at 50 psi

- Built in by-pass to tank

- Rebuildable Pump (Repair Kit Product No. P3001)

PCIIV: Rotary VANE Pump

1.7 gpm at 50 psi

System Features

- Plastic water tank eliminates coolant contamination due to electrolysis or chemical reactions.

- All units are plumbed with copper tubing and reinforced hose.

- New extended life pump features a direct drive power system reducing maintenance and vibration.

- No external plumbing is required because of closed loop water system.

- Self priming pump

- Easy change pump

- Strong rigid construction designed to support power unit.

- Compact design