Beckwood is more than a machinery manufacturer. We are a premiere hydraulic and servo-electric press builder who’s invested in your success. Our mission is to build and deliver better forming solutions that enable manufacturers to succeed.

We love to be challenged. We hate the word “no,” and we achieve the impossible every day. This passion, coupled with our unparalleled engineering and manufacturing ingenuity, allows us to build the best press solutions for your application.

Designing for Infinite Life

We design every hydraulic press structure to the Infinite Life classification using Finite Element Analysis (FEA) software. FEA is a computerized method for predicting how a press will react to external forces (vibration, heat, fluid flow, and other physical effects). By replicating real-world scenarios, Beckwood engineers are able to evaluate press performance, improve product quality, and test new ideas before a single piece is manufactured. If at any point during the engineering process the press’ structure does not meet the Infinite Life classification, the design is modified to account for structural deflection and stress.

The result is a machine that’s “Built for Life. Built in the USA.”

Quality Isn’t Easy

Our passion for excellence drives the continuous improvement of our Quality Management System (QMS). We use Six Sigma and 5S Lean Manufacturing Techniques to optimize our quality control process and improve the consistency, reliability, and efficiency of every press we build. Our QMS allows us to measure process variations, develop new systematic procedures, and ultimately, increase customer satisfaction.

Our rigorous QMS spans all aspects of the design/build process. Every Beckwood project is assigned a dedicated Project Manager whose sole mission is to ensure the finished machine exceeds your expectations for quality and performance. We conduct strategic departmental reviews at various milestones throughout the project and use a strict traceability system to verify every component is manufactured to the proper specifications. Once the press is built, our extended duration testing mimics real-world conditions to evaluate the press’ maximum rated capacity in an effort to uncover any issues prior to shipment.

Hydroforming is a metal forming process that uses pressurized hydraulic fluid in a flexible diaphragm to shape sheet metal against a single tool. The process can create a wide range of complex geometric shapes from a variety of materials including aluminum, steel, stainless, titanium, niobium, Inconel, copper, composites, and more.

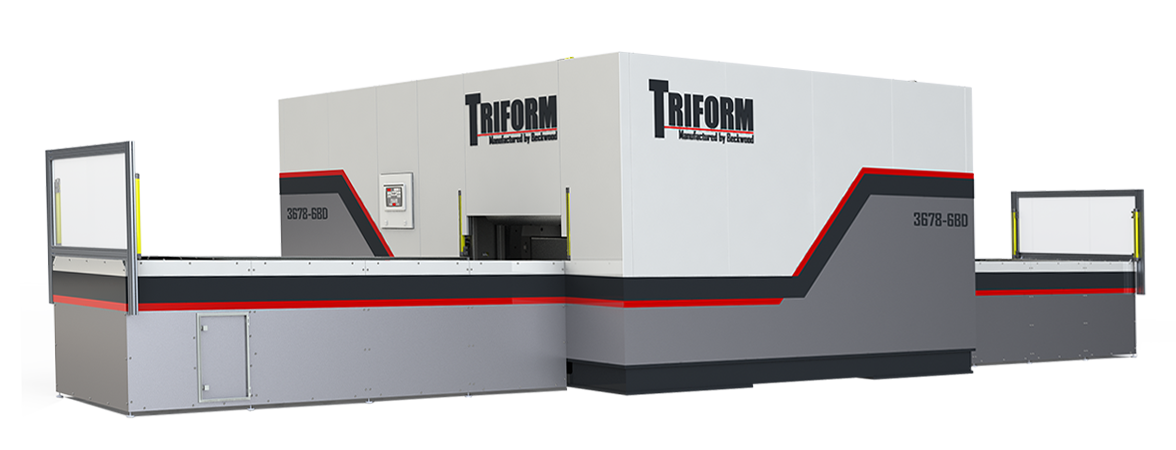

Beckwood’s standard line of Triform sheet hydroforming presses includes both fluid cell and deep draw configurations. Fluid cell sheet hydroforming creates shallow parts with open corners while deep draw sheet hydroforming is used for taller parts with closed corners and parts up to 15-inches tall.

Sheet hydroforming presses can combine and/or replace many different metal forming processes including press brakes, traditional draw forming, rubber pad forming, progressive die forming, and more. These machines can also consolidate multiple steps into a single cycle, virtually eliminating secondary finishing processes such as polishing, annealing, or welding.

The ability to react quickly and economically to production and new part development makes Triform Sheet Hydroforming the go-to technology for short-run part production and rapid prototyping.

The Triform 12-15-7DD deep draw sheet hydroforming press offers a 12 inch forming area, a punch tool diameter of 8.5 inches and a draw depth capacity of 7.5 inches. The 12-15-7DD offers 15,000 PSI of precision forming pressure.

The 12-15-7DD deep draw machine provides all of the “standard” luxuries of the Triform line including Triform’s proprietary “In-Sight” feature which allows you to stop the press and make a visual and physical inspection of a part during the forming sequence. This feature is excellent for part development and allows you to check the part to ensure your recipe is forming appropriately.