The Triform presses have been engineered using the latest technology. Modern design software, state-of-the-art hydraulics, and computer-driven controls provide the user with tremendous capability in an easy-to-operate package. The resulting hydroforming presses are offered in both Fluid Cell and Deep Draw Press configurations for use in a wide range of industries – aerospace, lighting, automotive, medical devices and more. Triform presses offer precision forming of a wide range of materials, with tooling cost savings of up to 90% through the elimination of mating dies.

Hydroforming press machinery can be used with both sheet and tube metal. This creates nearly limitless possibilities for forming very complex pieces of metal for a wide variety of products.This is one of the best ways to produce parts that require very tight tolerances such as parts for the automotive, aircraft, and aerospace industries.

If you are interested in pursuing the purchase of a Triform machine, the hydroforming specialists at Sanson Machinery are happy to discuss the goals and process of your metal fabrication application.

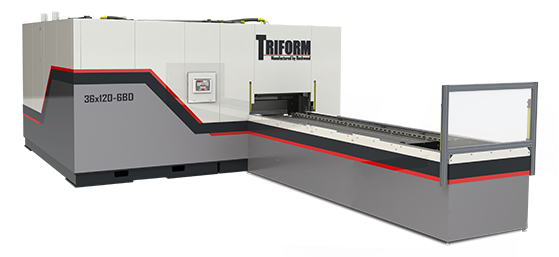

Model 36×120-6FC

The Triform Fluid Cell Sheet Hydroforming press model 36×120-6FC uses a dual shuttle system and urethane diaphragm to form large metal and composite parts for the aerospace, medical, and transportation industries. The oversized 36″ x 120″ rectangular forming area is the largest of all Triform’s fluid cell models. Form multiple smaller parts in a single cycle or parts up to 10′ long.

The 36×120-6FC is backed by Beckwood’s industry leading service and support and offers remote factory support to help eliminate downtime.

Features of Triform Fluid Cell Sheet Hydroforming Presses:

- Programmable Bladder Pressure

- System Diagnostics

- Alarm Handling and Logging

- Multi-level Password Protection

- PLC Input/ Output Visualization

- Batch Counter

- Average Cycle Timer

- Standard VPN connection via Ethernet allows for remote factory support through PressLink

Benefits of Triform Fluid Cell Sheet Hydroforming Presses:

- Bladder Forming Out-Performs Guerin Box or Pad Presses

- Simple to Operate Alternative to Press Brakes

- Low Tooling Costs with Greater Process & Part-Design Flexibility

- Compact Design Allows for Portability and Flush Floor Operation

- Durable, with Low Maintenance Requirements

- Fast Cycle Times

Model 20-10-10DD

The Triform 20-10-10DD deep draw sheet hydroforming press features a 20 inch round forming area and an incredibly capable 10,000 PSI of pressure. This deep draw press has a 10 inch punch stroke and 15.25 inch punch tool diameter. Allowing it to draw a multitude of parts.

The 20-10-10DD provides all of the “standard” luxuries of the Triform line including Triform’s proprietary “In-Sight” feature for physical inspection of a part during the forming sequence; but the most valuable feature of this press is likely the integrated tool change system which allows quick tool change-over. This change system can include a shuttle as well to help move multiple tools simultaneously. These features are designed specifically to benefit operations with high mix / low volume production.

This deep draw sheet hydroforming press is easy to operate and maintain. You will have worry free ownership knowing your equipment is backed by Beckwood’s industry leading service and support and offers PressLink for remote factory support.

Features of Triform Deep Draw Sheet Hydroforming Presses:

- System Diagnostics

- Alarm Handling and Logging

- Multi-level Password Protection

- PLC Input/ Output Visualization

- Batch Counter

- Average Cycle Timer

- Recipe storage up to 30 steps and 10,000+ recipes

- Sequential programming of pressure and punch position

- OEM set-up screen for remote support

- Standard VPN connection via Ethernet allows for remote factory support through PressLink

Benefits of Triform Deep Draw Sheet Hydroforming Presses:

- Able to operate in either fluid cell process mode or deep draw process mode

- Easy part development with proprietary “In-Sight” feature for visual inspection mid process

- Single tool technology – low tooling costs with greater process & design flexibility

- Durable, with low maintenance requirements

- Fast cycle times

Model 610-20-3DD

The Triform 610-20-3DD is the most compact deep draw sheet hydroforming press in Triform’s line-up, boasts a flush floor design, and offers the highest forming pressure available. This press comes standard with 20,000 PSI. It offers a 6″ x 10″ oval forming area with a draw depth up to 3 inches. These characteristics make it perfect for the formation of small parts as often needed in the medical, electrical, computer and aerospace industries.

The 610-20-3DD is a deep draw sheet hydroforming press offering all of the “standard” luxuries of the Triform line including simple programmability, recipe handling, and the ability to perform as a fluid cell sheet hydroforming press when the punch is removed. Like the other Triforms, it is backed by Beckwood’s industry leading service and support and offers remote factory support.

Triform Sheet Hydroforming has both Fluid Cell and Deep Draw Presses, offered in a variety or sizes and tonnage. Call Sanson Machinery Group to request a presentation.